A sustainable product in a sustainable way.

Together for more sustainability.

Effective environmental protection can only be achieved through sustainable business practices - something we at Resch have known since our founding in 1920. The conscientious handling of resources and the environment is a cornerstone of our company philosophy, and we take pride in being one of the pioneers in the development of sustainable solutions for the recycling of industrial packaging. Now in the 4th generation, we continue to follow the RESCH way and, together with our customers, make an important contribution to environmental protection in two ways. On one hand, we offer you a sustainable product, and on the other hand, through our processes, we contribute to promoting sustainability.

Resch - the partner for more sustainability.

Ecologically and economically sensible:

RECYCLE INSTEAD OF PRODUCE ANEW.

Both the environment and our customers benefit from our RESCH reconditioning cycle because, unlike new production, reconditioning offers many advantages. By utilizing reconditioning, our customers improve the environmental and waste balance of their companies, preserve resources, and reduce logistical effort through our pickup and delivery service.

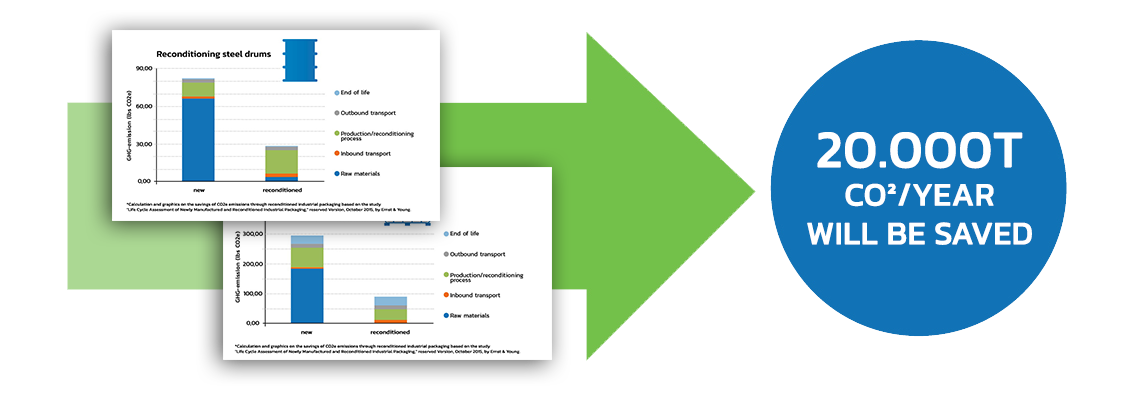

Reconditioning of steel drums: Minus 66% CO2 emissions.

Compared to new production, reconditioning steel drums generates approximately two-thirds less climate-damaging greenhouse gases.

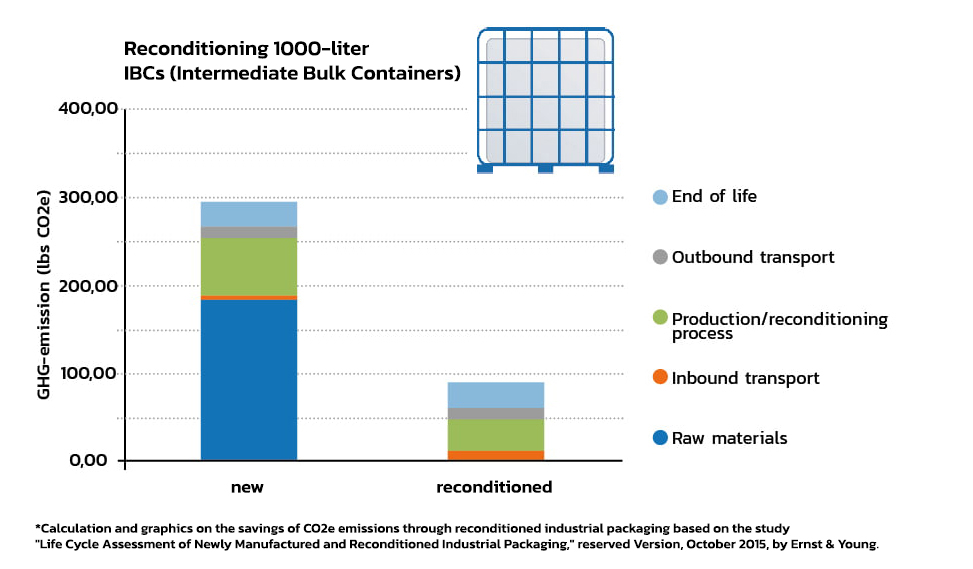

Reconditioning of IBCs: Minus 69% CO2 emissions.

Reconditioning IBCs results in a reduction of climate-damaging greenhouse gas emissions by more than two-thirds.

TOGETHER, WE ACHIEVE A LOT.

Thanks to our customers' decision to participate in the RESCH reconditioning cycle, we can make a significant contribution to emission reduction year after year through the collection and reconditioning of drums and IBCs.

*These figures are based on the average number of steel drums and

*These figures are based on the average number of steel drums andIBCs returned and reconditioned by RESCH each year.

Resch - the sustainable partner.

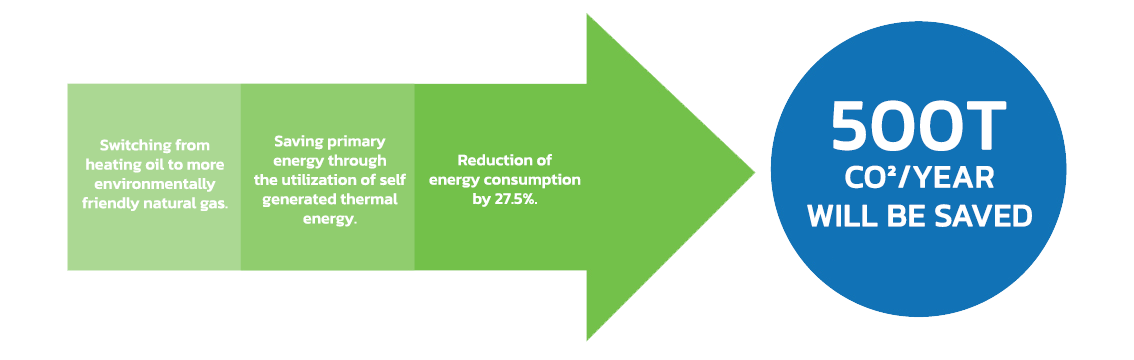

With continuous optimization of our work processes and the use of sophisticated technologies, we are able to reuse the thermal energy generated during reconditioning.

Previously unused -

now valuable energy.

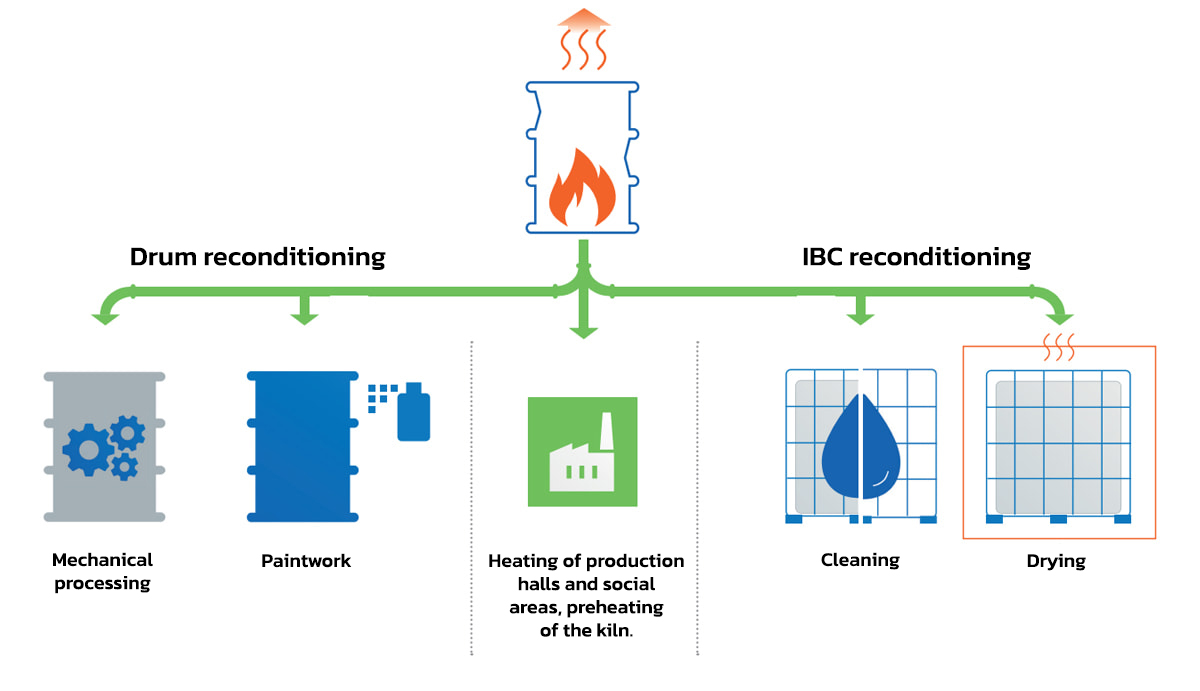

It has always been our endeavor to make our work processes as sustainable as possible. We constantly analyze our entire workflow, always looking for potential areas of improvement. As a result, we have developed solutions to efficiently utilize the excess thermal energy that is produced as a byproduct during the barrel firing process, ensuring that it is not wasted but rather put to good use in other processes.

Additionally, we continuously work on exploring further applications for the byproducts generated during our processes.

APPLICATIONS OF THERMAL ENERGY GENERATED

IN THE BURNING FURNACE THERMAL ENERGY

Step by step to even more sustainability

Sustainable business practices and environmentally friendly actions can only be achieved step by step, but when we continuously embark on this path, many small steps make a big difference.