Effectively reconditioning preserves valuable resources.

RECONDITIONING:

SAFE, reliable, SUSTAINABLE.

The aim of our RESCH reconditioning process is to clean and refurbish used, contaminated industrial packaging so that they can be reintroduced into the economic cycle as fully functional. Our processes are optimized to work in a resource-efficient manner while ensuring the highest levels of safety and quality.

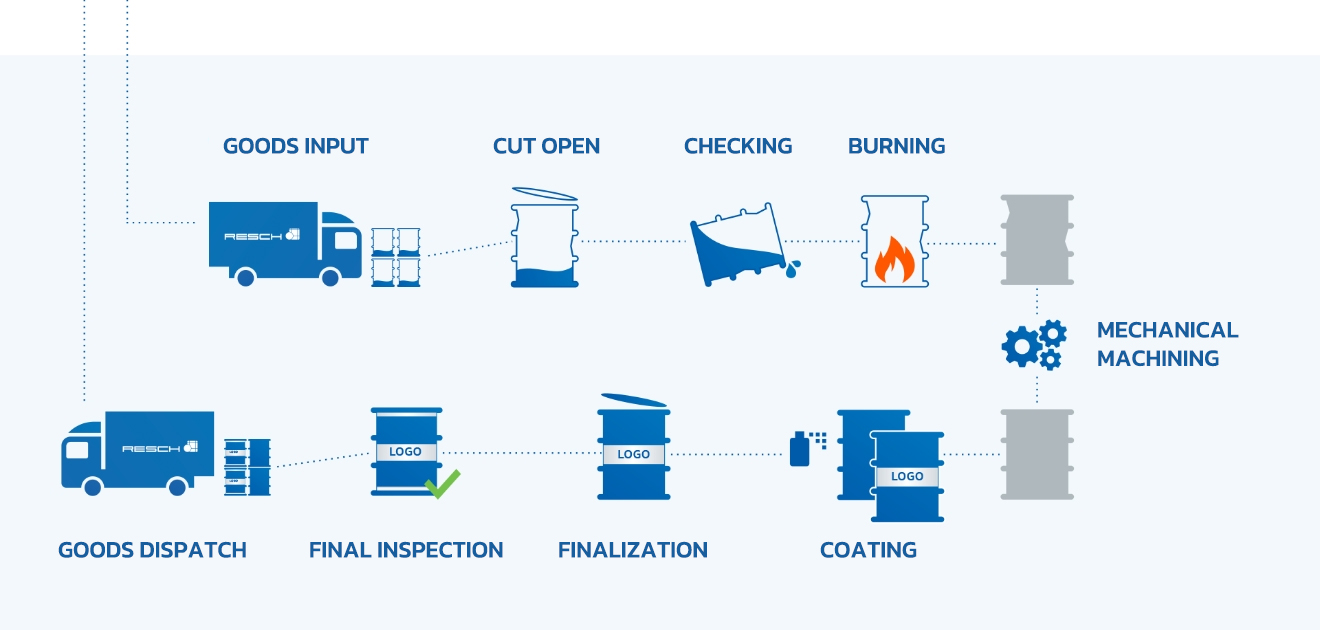

REFURBISHMENT OF STEEL DRUMS

The RESCH method for reconditioning used steel drums is unique in Germany. In this process, non-washable steel drums undergo thermal treatment (burning), which is the most effective way to preserve the value of the steel drums.

Efficient and flexible

Throughout our over 100-year company history, we have continuously optimized the reconditioning of steel drums. Through perfectly coordinated work steps, we are able to ensure high quality while conserving resources. However, we are also flexible enough to accommodate individual customer requests, such as specific certifications, at any time.

Not only is the reconditioning itself environmentally friendly and resource-efficient, but our work processes are as well. For instance, we utilize the exhaust air from the thermal afterburning system for:

| preheating the incineration furnace |

| drying in the barrel coating process |

| heating the hall |

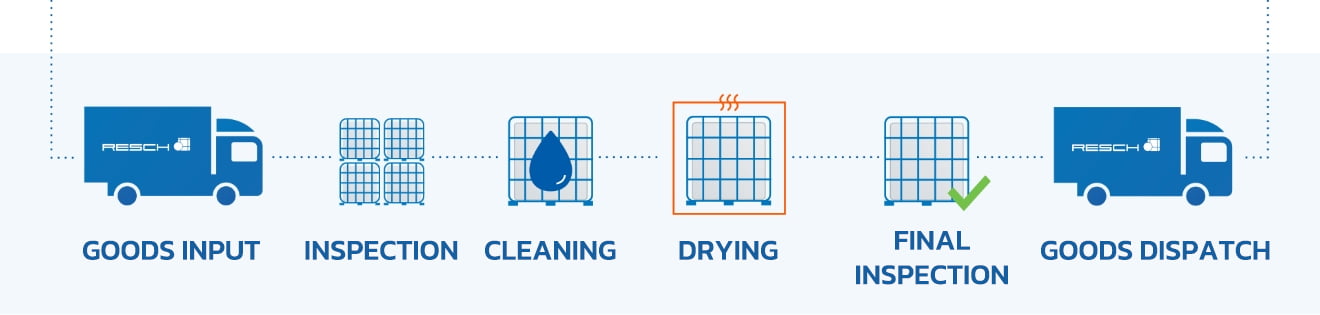

Reconditioning of IBC

As the leading German family-owned company in the reconditioning of industrial packaging, we follow a simple principle when it comes to reconditioning IBCs: "If washable, we wash. If not washable, we repair." By adhering to this principle, we pursue our goal of maximum sustainability.

Always our first choice: Cleaning.

Whenever possible, we clean the used IBCs, following the principle of "reuse before disposal," and we do so in the most resource-efficient manner. We only require water, alkaline solutions, and thermal energy, which is a byproduct of barrel production, to bring the IBCs back into full operational condition and reintroduce them into the economic cycle.

Not only is the reconditioning itself environmentally friendly and resource-efficient, but our work processes are as well. For instance, in the reconditioning of steel drums, we utilize the exhaust air from the thermal afterburning system for:

| cleaning of IBCs |

| drying of IBCs |

| heating the hall |

The alternative:

Rebottling and recycling.

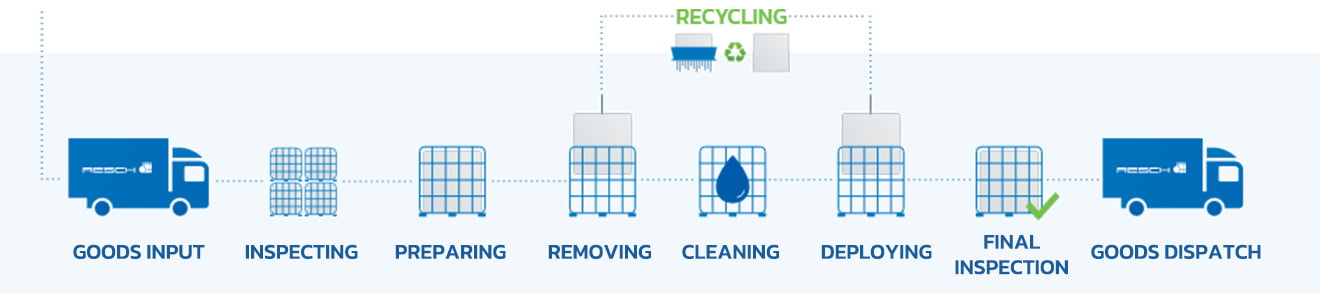

In cases where a retrieved IBC cannot be effectively cleaned, we employ the "rebottling" process.

In this process, the product-contacting components of the IBC, especially the plastic inner containers, are removed from the cage. The cage is cleaned and equipped with a brand-new inner bladder. The non-reusable components are recycled internally.

Not only is the reconditioning itself environmentally friendly and resource-efficient, but our work processes are as well. For example, in the reconditioning of steel drums, we utilize the exhaust air from the thermal afterburning system for:

| cleaning of IBCs |

| drying of IBCs |

| heating the hall |

Our goal: Resource-efficient processing and reuse of used plastic.

Following the principles of a circular economy, our processes are designed to recondition and reintroduce valuable resources back into the material cycle. Accordingly, the RESCH reconditioning cycle includes the material recycling of non-cleanable plastic packaging such as IBC inner bottles, plastic drums, or containers. These items are processed using state-of-the-art facilities to ensure they can be used as high-quality recycled materials by the plastic processing industry, especially packaging manufacturers.

Fast, secure, flexible - the collection of used industrial packaging is one of our most important service offerings in the reconditioning process.

Learn moreWhether you avail our reconditioning service or are independently interested in our industrial packaging, our competent advisors will help you find the right product that meets your requirements.

Learn More