Independent Family company for over

100 years.

100 years

of industry experience

Modern and innovative manufacturing facilities

BAM-approved manufacturer and reconditioning facility

Certified waste management company

ISO certified to 9001 and 14001

Future-oriented, Close-by, reliable.

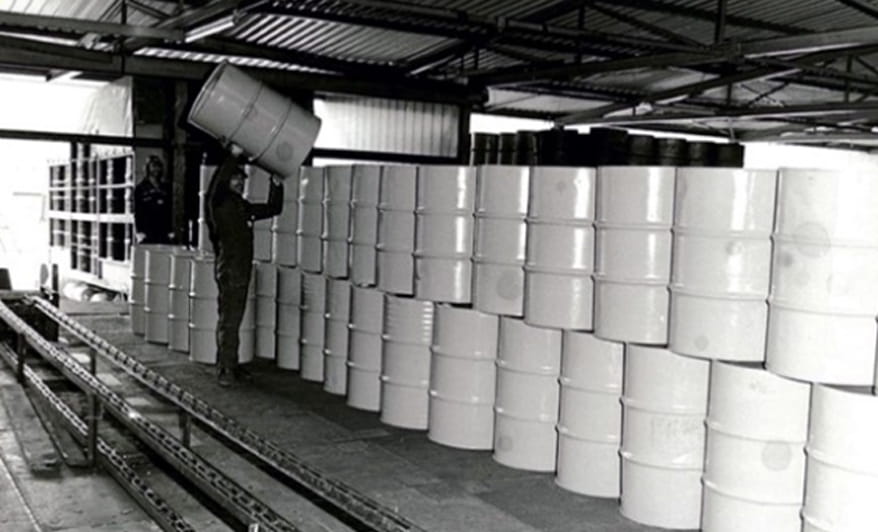

Currently in its fourth generation, Resch GmbH, headquartered in Schwerte, is one of the leading independent companies in the field of reconditioning steel drums and IBCs (Intermediate Bulk Containers). Since its establishment in 1920, the company has been dedicated to the philosophy of resource-efficient reconditioning rather than the labor-intensive production of industrial packaging. The drum reconditioning process employs a unique method that remains unparalleled in Germany to this day.

As a family-owned company with a long-standing tradition, our customers can rely on numerous advantages.

Future-oriented

| resource-efficient processes for reconditioning various industrial packaging | advanced technologies | continuous optimization of internal and external processes |

CUSTOMER PROXIMITY

| personalized consultation | customized solutions for customer needs | reliable, long-standing customer relationships | flexibility thanks to our own fleet of vehicles | central location in the Ruhr area |

reliable

| comprehensive portfolio in the industrial packaging sector | manufacturer-independent packaging take-back |

disposal in accordance with regulations | high quality standards | certified waste management company |

More than 100 years and currently in the fourth generation: continuous development has made us one of the leading companies in the field of reprocessing.

Certified safety

Proper disposal and reconditioning in all our reconditioning processes are essential and natural for us: As a certified waste management company, we comply with all environmental standards. In addition, we are certified according to ISO 14001:2015 for environmental management by TÜV Süd, and we are recognized by BAM (Federal Institute for Materials Research and Testing) as a manufacturer and reconditioner. The trust of our long-standing customers reinforces our principles.

Learn more about us

THE RESCH RECONDITIONING CYCLE.

Learn more

Become a part of our amazing team.

OUR JOB OPENINGS